How Does a Sludge Dewatering Centrifuge Work?

Written by AOS Treatment Solutions on August 21, 2018

Sewage disposal is one of the most ecologically important processes in the United States. The health of individuals and the environment depend on safe and effective ways to treat and dispose of this waste.

For decades, the focus has been on treating wastewater to control types of waterborne diseases and finding safe ways to incorporate the solid matter back into the environment. While improvements still need to be made to improve surface water and the wastewater infrastructure, reliable equipment already exists to handle this process.

Sludge dewatering centrifuges are central to proper municipal wastewater treatment, so residents, business management, and government officials should understand how they work as well as their strengths and weaknesses.

What is a Sludge Dewatering Centrifuge?

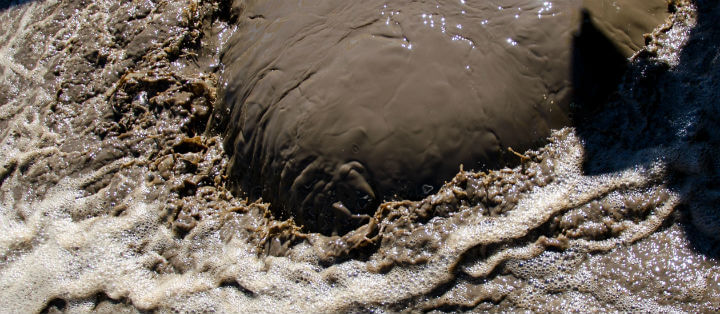

A sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake. Dewatering means less tank space is needed to store waste products.

According to the EPA, the dewatered sludge may be slightly loose, like custard, or firmer, like moist soil.

Advantages and Disadvantages of Centrifugation Method

There are several advantages and disadvantages of centrifugation in wastewater treatment.

Advantages of a Dewatering Centrifuge

The centrifuge method has numerous advantages. Private contractors report savings of approximately 75% on transport costs and approximately 80% on disposal costs after changing to the sludge centrifuge method of dewatering. The equipment can be placed close to the contractor’s base of operation, allowing for greater convenience and increased productivity.

The cake produced by this process is easy to move to a landfill, or it can be mixed with green waste and composted. The filtrate can be used on the soil during a drought, recycled and used by a jetting system or discharged to a foul system.

This method also works for all sludge types, increases dry solids content, and provides wastewater sludge dewatering without a filtering medium.

Disadvantages of a Continuous Centrifugal Separator

The method does have some significant limitations, including high wastewater treatment energy consumption, noise issues, and, in some instances, the need for a standby unit.

While maintenance needs are minimal, they are specialized, which can cause repair delays and other difficulties.

Difference Between Centrifuge and Filter Press

A filter press has a completely different design than a centrifuge, with the waste products fed into a hopper where the sludge is pressed between two filter cloths. Gravity and rollers remove the fluid from the dewatering press. The filtrate goes out a drain, and the solids are put into a container.

While centrifuges cost less to operate and provide lower cake moisture content, filter presses can be started and shut down more quickly and run more quietly. They also are reliable and may be easier to maintain than a centrifuge because they require less specialized care.

Municipal and industrial clients can talk about the right treatment systems for their needs by contacting the wastewater treatment consultants at AOS. Our services include clarification, sludge dewatering applications, phosphorus removal, odor control, and the chlorination/dichlorination of wastewater.

AOS provides the latest technology and treatment methods for clients that include private businesses, public corporations, and government agencies. We have the experience and expert team to address any treatment challenge.

For more information on our services, call (936) 228-6539 or contact us online today!